Irmo homeowners face persistent gutter maintenance challenges from the area’s mature tree coverage, humid climate, and architectural complexity. Installing gutter protection systems Irmo SC properties increasingly rely on transforms this ongoing burden into minimal-maintenance convenience while providing superior home protection. Understanding how different protection systems work, their performance in Irmo’s specific conditions, and how to select optimal solutions helps you make informed investment decisions that deliver promised benefits.

Understanding Gutter Protection Systems

Before comparing specific options, understanding fundamental principles and terminology provides context for evaluating different approaches to gutter protection.

What Are Gutter Protection Systems?

Gutter protection systems encompass various products designed to keep debris out of gutters while allowing water to flow freely into drainage systems. The terminology varies across the industry—”gutter guards,” “gutter covers,” “leaf guards,” and “gutter protection” often describe the same general category. These systems act as barriers preventing leaves, pine needles, seed pods, and other debris from entering gutters where they’d create clogs and require frequent removal.

The fundamental goal is consistent: maintain gutter function without regular manual cleaning. However, approaches vary dramatically. Some systems use fine screening to physically block debris while allowing water through small openings. Others employ surface tension principles where water adheres to curved surfaces and enters gutters while solid debris lacks the adhesion to follow the same path. Some fill gutters with porous materials allowing water to filter through while blocking larger debris.

Understanding that “gutter protection” represents a category with diverse approaches rather than a single product type helps you evaluate options critically. Marketing claims of “maintenance-free” or “never clean your gutters again” should be viewed skeptically—even the best systems reduce but don’t completely eliminate maintenance. Quality systems dramatically reduce cleaning frequency and effort, transforming quarterly cleanings into occasional inspections every few years.

How Protection Systems Work

Effective protection relies on engineering principles rather than simple physical barriers. The best systems exploit differences between water and solid debris. Water exhibits surface tension and adhesion—it clings to surfaces and can follow curves. Solid debris lacks these properties and can only travel via momentum. Quality systems are designed so water’s adhesive properties cause it to follow guard surfaces into gutters while debris falls away or rests on top where it can be easily removed.

Opening size is critically engineered. Too large and debris enters defeating the purpose. Too small and water flow capacity suffers causing overflow during heavy rain. Quality systems balance these factors, typically featuring openings sized to block debris common in their target market while processing water volumes typical of regional rainfall patterns. Columbia-area systems should handle 20-25 inches of rainfall per hour—the intensity of summer thunderstorms.

Material selection affects performance significantly. Stainless steel resists corrosion indefinitely and maintains structural integrity across temperature ranges. Aluminum provides good performance at moderate cost. Plastics and vinyl are vulnerable to UV degradation and temperature-related brittleness over time. Installation angle and pitch affect water entry—proper installation following manufacturer specifications is as critical as product quality for optimal performance.

Types of Protection Available

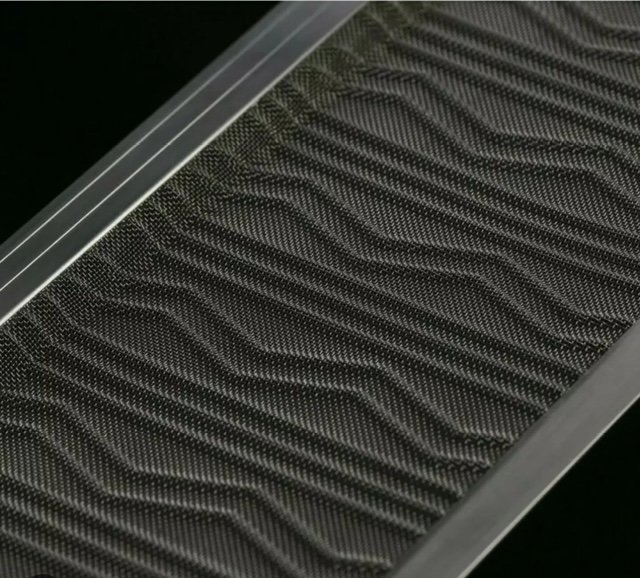

The market offers several distinct approaches to gutter protection, each with unique characteristics. Micro-mesh systems feature surgical-grade stainless steel screening with openings measured in microns—finer than human hair. These premium systems block virtually all debris while maintaining excellent water flow when properly installed. Screen systems use perforated metal or plastic with larger openings blocking leaves and large debris but potentially allowing pine needles and small particles through.

Reverse curve or surface tension systems feature solid covers with narrow openings at forward edges. Water follows the curve into gutters while debris falls to the ground. Foam inserts fill gutters with porous material allowing water to filter through while blocking debris—inexpensive but with significant performance limitations. Brush guards look like oversized pipe cleaners sitting in gutters, catching debris while water flows around bristles.

Each type offers different balances of cost, performance, and maintenance requirements. Understanding these fundamental differences helps match systems to your specific property needs rather than being swayed by marketing claims or aggressive sales tactics. When researching gutter protection systems near me, prioritize understanding which system types perform best in Irmo’s conditions rather than focusing solely on price.

Irmo-Specific Benefits

Irmo’s characteristics make gutter protection particularly valuable beyond general maintenance convenience. The area’s mature tree canopy creates year-round debris accumulation—not just seasonal challenges. Pines drop needles continuously, oaks shed leaves and acorns, sweetgums deposit spiky seed pods. Without protection, this diversity of debris types requires frequent cleaning to maintain function.

Lake Murray’s proximity contributes to humidity that accelerates organic decomposition in gutters and promotes algae growth. Protection systems that keep gutters clear and flowing prevent the standing water and organic buildup that thrive in humid conditions. Many Irmo homes feature two-story construction or complex rooflines making safe cleaning extremely challenging. Protection eliminates most need for dangerous elevated work.

Irmo’s established neighborhoods feature substantial home values where property condition significantly impacts marketability. Well-maintained homes with modern protection systems appeal to buyers wanting low-maintenance properties. The investment in quality protection preserves property values while reducing ongoing maintenance burdens—particularly valuable for Irmo’s demographic including many aging homeowners who’ve maintained properties for decades but want to reduce physical demands without relocating.

Comparing Gutter Protection System Options

Understanding how different system types compare in performance, cost, and maintenance helps you select options matching your priorities and circumstances.

Micro-Mesh Protection Systems

Micro-mesh represents the premium option featuring stainless steel screening with openings as small as 50 microns—far finer than pine needles or other small debris common in Irmo. This extremely fine mesh blocks virtually everything while maintaining excellent water flow when properly installed with correct pitch. The mesh typically installs under first row of roof shingles, providing comprehensive coverage across entire gutter width.

Performance is superior—micro-mesh handles Irmo’s diverse debris types effectively including pine needles that penetrate other systems, oak leaves and acorns, sweetgum seed pods, and roof grit and sediment. It processes high water volumes handling Lake Murray area storm intensity without overflow. Durability is exceptional—quality stainless steel systems last 20-30 years matching gutter lifespan. They resist corrosion in Irmo’s humidity indefinitely.

Maintenance requirements are minimal—occasionally brushing accumulated debris from top surface once or twice yearly even with heavy tree coverage. This simple maintenance takes minutes from the ground without climbing ladders. Cost is highest among options—typically $15-$25 per linear foot installed or $2,250-$3,750 for average 150-foot system. However, performance and longevity justify investment for Irmo’s challenging conditions. For properties with mixed vegetation including pines requiring needle protection, micro-mesh provides the only reliable long-term solution.

Reverse Curve and Surface Tension Systems

Reverse curve systems feature solid covers with narrow openings at forward edges. Water follows the curve into gutters via surface tension while debris falls to ground. These systems handle large leaves and heavy water volume well when properly installed. They’re suitable for properties with primarily large-leaf trees and minimal pine coverage.

However, they have limitations in Irmo’s mixed vegetation. Very fine debris like pine needles or roof grit may occasionally enter openings. Strong winds can blow lightweight leaves into openings. Performance depends heavily on installation quality—improper pitch dramatically affects function. Some local codes restrict reverse curve systems due to ice dam concerns, though this is less relevant in Irmo’s mild winters.

Cost is comparable to micro-mesh—typically $15-$30 per linear foot installed. Performance is good for specific situations but less versatile than micro-mesh for Irmo’s typical mixed tree species. Maintenance is minimal when working properly but may require periodic inspection ensuring openings remain clear. For properties with primarily oaks and minimal pines, reverse curve performs adequately. For typical Irmo properties with diverse vegetation, micro-mesh provides more comprehensive protection.

Screen and Filter Systems

Screen systems with moderate-sized openings (1/4 inch to 1/2 inch) provide basic protection at moderate cost—typically $7-$12 per linear foot installed. They block leaves and large debris but allow pine needles, small seeds, and roof grit through. This means reduced but not eliminated cleaning needs—properties might need annual cleaning versus quarterly without protection.

Performance in Irmo’s pine-heavy environment is marginal—needles penetrate screens creating the same clogs protection was supposed to prevent. Screens work acceptably for properties with primarily large-leaf trees and minimal pine coverage. Durability varies by material—aluminum screens last well while plastic options may become brittle with UV exposure in 10-15 years.

Maintenance requirements exceed premium systems—annual inspection and cleaning of accumulated small debris. Some debris may need removal from beneath screens where it’s collected in gutters. Cost savings versus micro-mesh are modest—typically $1,200-$600 for complete systems. For Irmo’s conditions, the limited performance improvement over unprotected gutters makes screens questionable value. They reduce but don’t solve the maintenance burden.

Foam and Brush Insert Options

Foam inserts fill gutters with porous material allowing water to filter through while blocking debris. They represent the lowest-cost option at $4-$8 per linear foot for materials, though professional installation adds labor costs. Installation is simple—pieces are cut to length and placed in gutters. However, foam has significant limitations making it unsuitable for permanent Irmo installations.

UV exposure degrades foam in 5-10 years requiring replacement. Fine debris trapped within foam structure creates mud-like accumulation restricting flow. Seeds and vegetation may grow in trapped debris and foam material. Foam eventually requires removal for cleaning or replacement—dirty, messy task. Performance in Irmo’s humid conditions is poor—organic growth thrives in foam’s porous, moisture-retaining structure.

Brush inserts featuring stiff bristles provide similar concept with different materials. They last longer than foam—typically 10-15 years—but trap fine debris requiring eventual removal and cleaning. Both options suit temporary situations or extreme budget constraints but aren’t recommended for permanent residential installations. For Irmo homeowners seeking long-term protection solutions, investing in quality micro-mesh or reverse curve systems provides dramatically better value despite higher initial costs.

Performance in Irmo’s Unique Environment

Irmo’s specific conditions affect protection system performance in ways that should guide your selection process.

Handling Heavy Tree Debris

Irmo’s mature tree coverage creates diverse debris challenges. Oak trees drop enormous leaf volumes in fall plus acorns year-round. Pine trees shed needles continuously—not seasonally—requiring protection that handles ongoing accumulation. Sweetgum seed pods are sticky and spiky, difficult to remove once lodged in gutters. Various other species contribute additional debris types.

Micro-mesh excels in this mixed environment, blocking all debris types from large oak leaves to fine pine needles. The fine screening is engineered to allow dried debris to blow off or be easily brushed away while maintaining water entry. Accumulated leaves don’t mat down blocking water—they remain on top of mesh and can be removed with leaf blower or soft brush from ground level.

Reverse curve systems handle oak leaves acceptably but struggle with pine needles that may enter openings. Screen systems allow needle penetration—providing marginal benefit for pine-heavy properties. Foam and brush inserts trap fine debris becoming progressively clogged. For Irmo’s typical mixed vegetation, micro-mesh provides comprehensive protection while other systems offer incomplete solutions requiring ongoing cleaning similar to unprotected gutters.

Managing Lake Murray Area Humidity

Lake Murray’s proximity contributes to local humidity affecting both gutter conditions and protection system materials. Standing water in unprotected gutters promotes algae growth, accelerates aluminum corrosion, and creates unpleasant conditions. Quality protection systems prevent debris accumulation that causes standing water, maintaining better gutter hygiene in humid environments.

Material selection matters in humid conditions. Stainless steel micro-mesh resists corrosion indefinitely regardless of humidity. Aluminum components with quality finishes perform well. Plastic and vinyl components are more vulnerable—humidity accelerates UV-related degradation causing brittleness. Foam inserts are particularly problematic—the porous, moisture-retaining structure promotes organic growth and deterioration in humid climates.

Some protection surfaces promote algae or moss growth in humid conditions. Quality micro-mesh’s tight weave and stainless material resist biological growth. Smooth surfaces shed growth better than textured ones. When selecting systems for Irmo properties, consider long-term performance in humidity rather than just initial appearance and cost. Materials and designs proven in humid coastal or lakeside environments provide better assurance of reliable performance in Irmo’s conditions.

Performance During Intense Storms

Summer thunderstorms around Lake Murray can be intense, dumping several inches of rain in short periods. Protection systems must handle this high-volume flow without causing overflow—the point of gutters is collecting and channeling water, not protecting gutters at the expense of overall function.

Quality micro-mesh systems are engineered and tested to process 20-25+ inches of rainfall per hour—far exceeding even the heaviest Irmo storms. The fine mesh doesn’t restrict flow when properly installed with adequate pitch. Water flows through the mesh into gutters efficiently. Reverse curve systems handle high volume well when properly pitched—the entire opening width is available for water entry.

Screen systems with larger openings process water well but may accumulate debris between storms reducing capacity when it’s most needed. Foam and brush inserts can restrict flow if they’ve trapped fine debris—potentially causing overflow during intense rain. Proper installation is critical—even quality systems fail if installed with inadequate pitch. Professional installers familiar with Irmo’s rainfall intensity ensure systems are pitched appropriately for local conditions, providing confidence your protection won’t compromise performance during storms.

Durability in Local Climate

Irmo experiences temperature ranges from occasional winter freezes to summer highs exceeding 95°F. Quality protection systems must maintain performance across this range throughout 20-30 year lifespans. Lake area winds test attachment security. Abundant rainfall creates persistent moisture exposure. These conditions demand durable materials and secure installation.

Stainless steel and quality aluminum maintain properties across temperature ranges without warping, cracking, or degrading. They handle wind stress when properly attached. Plastic components may become brittle in winter cold or soften in summer heat leading to failure. Vinyl systems often crack or warp within 10-15 years in Irmo’s UV exposure and temperature variations.

Attachment method affects durability. Systems secured under roof shingles resist wind uplift better than surface-mounted options. Hidden hangers provide more secure attachment than external brackets. Professional installation ensures attachment withstands Irmo’s weather throughout system lifespan. When evaluating protection options, consider total lifespan costs rather than just initial investment—systems requiring replacement after 10 years cost more long-term than durable systems lasting 25-30 years despite higher upfront pricing.

Cost-Benefit Analysis for Irmo Homeowners

Understanding financial aspects helps evaluate protection systems as investments rather than simple expenses, considering both immediate costs and long-term value.

Installation Investment by System Type

Protection system costs vary significantly based on type, materials, and installation complexity. For typical Irmo homes with 150 linear feet of gutters, expect the following installed costs. DIY foam or brush inserts cost $600-$1,200 for materials only—lowest initial cost but shortest lifespan and marginal performance. Professional screen installation runs $1,050-$1,800—moderate cost with limited effectiveness for pine-heavy properties.

Quality micro-mesh systems cost $2,250-$3,750—premium price for superior comprehensive protection. Reverse curve systems range from $2,250-$4,500 depending on brand and features. Two-story homes or complex rooflines increase costs by 20-40% due to additional installation challenges. These prices include complete professional installation by licensed, insured contractors.

Material-only prices for DIY installation are substantially lower but don’t include professional expertise ensuring optimal performance. Quality systems like micro-mesh require professional installation—they attach under shingles and improper installation causes roof problems or compromises performance. Screen systems might work for experienced DIYers but professional installation still provides better results and warranty protection.

Maintenance Savings Over Time

Calculate long-term savings by comparing current maintenance costs against reduced needs with protection. Without protection, heavily treed Irmo properties typically need quarterly professional cleaning at $200-$300 per service, totaling $800-$1,200 annually. Properties with moderate coverage need bi-annual service at $400-$600 yearly. Over 20 years, maintenance costs total $8,000-$24,000 depending on property conditions.

Quality micro-mesh protection reduces cleaning to once every 2-3 years for inspection at $150-$200 per visit—annual costs of $50-$100 or $1,000-$2,000 over 20 years. Even accounting for occasional guard surface brushing (simple ground-level task), savings are substantial—typically $7,000-$22,000 over system lifespan. Time savings if you currently clean gutters yourself represents additional value—recovering dozens of hours over decades.

These savings don’t include prevented damage from better-functioning gutters. Even one avoided foundation repair costing $10,000+ dramatically improves protection system returns. Guards ensure consistent drainage protecting foundations, fascia, and landscapes even when you can’t clean gutters before storms. This reliable protection provides value beyond simple maintenance savings.

Return on Investment Timeline

ROI depends on system cost and current maintenance frequency. Typical scenario: $3,000 micro-mesh installation, $800 annual cleaning cost eliminated, $100 annual inspection cost with guards. Simple payback: approximately 4 years through cleaning savings alone. However, full ROI calculation includes prevented damage from consistent protection, extended gutter lifespan from reduced stress, and added home value from low-maintenance systems.

Over quality systems’ 20-25 year lifespan, total ROI often exceeds 400-600% considering all factors. For heavily treed Irmo properties currently requiring quarterly cleaning, payback periods are even shorter—sometimes under 3 years. For properties with minimal trees needing only annual cleaning, payback extends to 6-8 years but value proposition remains strong considering decades of reduced burden and superior protection.

Property-specific factors affect individual calculations but for most Irmo homeowners with significant tree coverage, protection systems provide compelling financial returns beyond convenience benefits. When you consider guards reduce physical demands, improve safety by eliminating frequent ladder work, and provide peace of mind through reliable storm protection, the value proposition becomes even stronger particularly for aging homeowners wanting to remain in homes without maintenance burdens.

Impact on Property Value

Protection systems affect property values through multiple mechanisms. They reduce buyer maintenance concerns—homes with quality protection systems appeal to buyers wanting low-maintenance properties. They prevent damage that affects marketability—well-maintained drainage protects foundations, fascia, and landscapes. They provide marketing advantages—professional protection installation can be highlighted during sales.

Quality systems from reputable manufacturers with transferable warranties add particular value. Documentation of professional installation and any service history demonstrates responsible homeowner ship. In Irmo’s competitive real estate market where condition significantly impacts pricing, the relatively modest protection investment helps maintain premium valuations.

While protection systems don’t provide dollar-for-dollar value recovery at sale—few home improvements do—they prevent value loss from poor maintenance and appeal to quality-conscious buyers. For Irmo properties in the $300,000-$600,000+ range typical of established neighborhoods, protecting that substantial value through $3,000-$4,000 protection system investment represents prudent financial management with multiple returns including reduced maintenance, prevented damage, and maintained property appeal.

Installation and Maintenance Considerations

Proper installation determines whether systems deliver promised performance. Understanding installation and ongoing care requirements ensures successful long-term results.

Professional Installation Requirements

Quality protection installation requires professional expertise and equipment. Installers need commercial ladders with stabilizers and proper safety equipment for elevated work, specialized tools for precision gutter and roof work, understanding of proper pitch requirements ensuring water flows correctly, and knowledge of appropriate attachment methods for different roof types preventing damage while ensuring security.

Professional installation includes cleaning gutters thoroughly before protection installation, inspecting and repairing any gutter damage, installing protection with correct pitch and secure attachment, sealing attachment points preventing leaks, testing with water verifying proper function, and providing detailed warranty documentation. This comprehensive approach ensures systems perform as designed rather than disappointing due to installation shortcuts.

DIY installation seems cost-effective but risks improper pitch compromising drainage, attachment methods damaging roofs or voiding warranties, inadequate sealing creating problems, safety hazards from elevated work, and voided manufacturer warranties requiring professional installation. For most Irmo homeowners, professional installation provides better value through proper execution, warranty protection, and peace of mind.

Compatibility with Existing Gutters

Most protection systems can be installed on existing gutters if they’re in good condition. Professional installers first assess gutter condition including proper pitch and slope, secure attachment to fascia, absence of significant leaks or damage, and structural soundness throughout system. If gutters are sagging, leaking extensively, or damaged, repairs or replacement may be necessary before protection installation.

Installing protection on compromised gutters wastes money—systems can’t perform properly on failing infrastructure. Some older or non-standard gutter profiles may not accept certain protection systems—installers assess compatibility during estimates. If your gutters are over 20 years old or showing significant wear, consider replacing them when adding protection for comprehensive long-term solution providing decades of combined reliable service.

Ongoing Maintenance Needs

While protection systems dramatically reduce maintenance, they’re not completely “maintenance-free” despite marketing claims. Quality micro-mesh systems need occasional debris brushing from top surface once or twice yearly in heavy debris areas—simple ground-level task with leaf blower or soft brush taking minutes. They benefit from annual visual inspection checking for any damage or accumulated debris. Professional inspection every 2-3 years ensures optimal function.

Reverse curve systems need periodic checking ensuring openings remain clear. Screen systems may require more frequent debris removal from surfaces or beneath screens. Foam and brush inserts eventually need removal for cleaning or replacement—labor-intensive, messy task. When comparing systems, consider long-term maintenance requirements and total cost of ownership rather than just initial investment. Systems requiring minimal maintenance provide better value through reduced ongoing time and cost commitments.

Warranty Coverage

Quality protection installations include comprehensive warranties. Material warranties typically cover 20-30 years or lifetime for premium products protecting against defects, corrosion, and structural failure. Workmanship warranties cover installation quality for 1-5 years addressing any performance issues from improper installation. Some manufacturers offer performance guarantees promising gutters won’t clog during warranty period—demonstrating confidence in product effectiveness.

Understand warranty claim procedures—how to report problems and what documentation is required. Verify warranty transferability if you sell your home—this adds value for buyers. Get warranty terms in writing as part of your installation contract. Quality manufacturers and installers stand behind their products and work through meaningful warranties and responsive service. They view warranties as protecting their reputations rather than unwelcome obligations. Strong warranties indicate confidence in product and installation quality.

Selecting the Right Protection System

Choosing appropriate systems ensures you receive expected benefits rather than disappointing results. Understanding selection factors helps match systems to your specific needs.

Assessing Your Property’s Needs

Consider multiple factors when evaluating options. What debris types threaten your gutters? Irmo properties with heavy pine coverage need systems excelling at needle exclusion—micro-mesh performs best. Properties with primarily oaks do well with various systems. How much rainfall must systems handle? Lake Murray area storms require high-capacity systems—quality micro-mesh and reverse curve handle intense rain well.

What’s your maintenance tolerance? If you want minimal involvement, invest in premium systems requiring almost no attention. If you’re willing to occasionally brush debris from surfaces, more options work. What’s your budget for both installation and long-term costs? Higher upfront investment in quality systems typically provides better long-term value through reduced maintenance and superior performance.

How long do you plan to stay in your home? Long-term residents benefit most from premium systems providing decades of service. Shorter-term homeowners might choose moderate options. Do you have physical limitations making ladder use difficult? Protection provides particular value for aging homeowners or those with mobility issues eliminating dangerous elevated work.

Choosing Based on Tree Coverage

Tree coverage significantly affects optimal system selection. Properties with heavy pine presence absolutely need micro-mesh—it’s the only system reliably blocking pine needles. Properties with primarily large-leaf trees like oaks have more options—micro-mesh, reverse curve, or quality screens all work reasonably well. Properties with mixed vegetation typical of most Irmo locations benefit from micro-mesh’s versatility handling all debris types.

Consider not just current trees but neighbors’ trees and future growth. Young trees will mature creating more debris over time. Nearby properties with overhanging branches contribute to your accumulation. When evaluating protection, think 20+ years ahead rather than just current conditions. Systems that work adequately now but struggle as trees mature provide poor long-term value. Micro-mesh’s comprehensive protection makes it the safe choice for long-term Irmo installations regardless of specific current tree composition.

Finding Quality Installers in Irmo

Select installers carefully to ensure quality results. Look for local experience—contractors familiar with Irmo understand area challenges, have local references you can contact, and understand Lake Murray weather patterns. Verify proper licensing and comprehensive insurance—essential protections for you and workers. Check multiple review sources including Google, Facebook, and Better Business Bureau—look for consistent positive feedback.

Request detailed written estimates specifying exact materials and brands, complete installation scope, warranty terms for materials and workmanship, payment schedule, and project timeline. Compare total value rather than just bottom-line price—lowest bidders often cut corners. Ask about post-installation service and support—quality companies provide ongoing assistance throughout system lifespan.

Questions to Ask Before Installation

Interview potential installers before committing. Ask about their experience with specific system types you’re considering—not all contractors install all systems equally well. Request local references from recent installations—contact these homeowners asking about satisfaction and performance. Ask how they handle Irmo’s specific conditions—pine needles, intense rain, humidity effects.

Inquire about their installation process—how do they ensure proper pitch? How do they attach systems to different roof types? What testing do they perform? Ask about maintenance requirements—what will you need to do to maintain optimal performance? Discuss warranty claims—how are problems handled? These questions reveal professionalism and help you understand what to expect from both installation and long-term system performance.

Key Takeaways

- Micro-mesh stainless steel systems provide the only reliable protection for Irmo’s heavy pine needle coverage while also handling oak leaves and mixed debris—justifying their $2,250-$3,750 cost through comprehensive protection that cheaper alternatives can’t match in local conditions.

- Protection systems save $7,000-$22,000 over 20 years through reduced cleaning costs while eliminating safety risks of frequent ladder work and providing consistent drainage protecting foundations, fascia, and landscapes even when you can’t clean before storms.

- Professional installation by experienced local contractors ensures proper pitch, secure attachment, and optimal performance—the modest installation premium delivers value through correct execution, warranty protection, and long-term service support throughout system’s 20-30 year lifespan.

Frequently Asked Questions

Q: Will gutter protection systems really eliminate the need for gutter cleaning in Irmo?

A: Quality systems dramatically reduce but don’t completely eliminate maintenance despite “never clean again” marketing claims. Premium micro-mesh systems reduce cleaning frequency from 2-4 times annually to once every 2-3 years for inspection rather than actual cleaning. Between inspections, you may need to brush accumulated debris from guard surfaces once or twice yearly—simple ground-level task taking minutes rather than hours of gutter cleaning. No system is truly “maintenance-free” in Irmo’s heavily treed environment. However, the maintenance reduction is substantial—transforming significant ongoing burden into minimal occasional attention. For Irmo properties currently requiring quarterly professional cleaning at $800-$1,200 annually, systems reducing this to $50-$100 yearly for surface brushing and occasional inspection provide tremendous value beyond complete elimination being unrealistic expectation.

Q: How do gutter protection systems perform during Lake Murray area storm intensity?

A: Quality systems are specifically engineered to handle high-volume rainfall typical during intense thunderstorms. Premium micro-mesh systems are tested to process 20-25+ inches of rainfall per hour—far exceeding even the heaviest storms Irmo experiences. The key is proper installation with correct pitch ensuring water flows into gutters rather than overshooting. Lake Murray storms can be intense, but properly installed protection maintains full gutter capacity regardless of recent debris accumulation. This means consistent protection even during unexpected heavy rain when you haven’t had opportunity to check gutters. In fact, protection improves storm performance compared to unprotected gutters that may be partially clogged reducing capacity. The combination of high-capacity guards and clean gutters provides optimal storm protection. Professional installation ensures your system is pitched and sized appropriately for local rainfall intensity and your roof’s water volume.

Q: What’s the best gutter protection system for Irmo homes with lots of pine trees?

A: Micro-mesh stainless steel systems are the only reliable long-term solution for Irmo properties with significant pine tree coverage. Pine needles are small enough to penetrate screen guards with larger openings, reverse curve system openings, and brush/foam inserts—these alternatives provide minimal benefit for pine-heavy properties. Micro-mesh with openings measured in microns (finer than human hair) blocks pine needles completely while maintaining excellent water flow during rain. The needles accumulate on mesh surface but dry and blow away or can be easily brushed off ground level once or twice yearly. This minimal maintenance dramatically beats cleaning needle-filled gutters quarterly. For Irmo’s abundant pines—extremely common throughout the area—micro-mesh represents the only choice delivering promised maintenance reduction. Cheaper alternatives that allow needle penetration waste money providing marginal improvement over unprotected gutters. The $2,250-$3,750 micro-mesh investment provides decades of reliable protection specifically needed for Irmo’s pine challenge.

Mr. Gutter SC